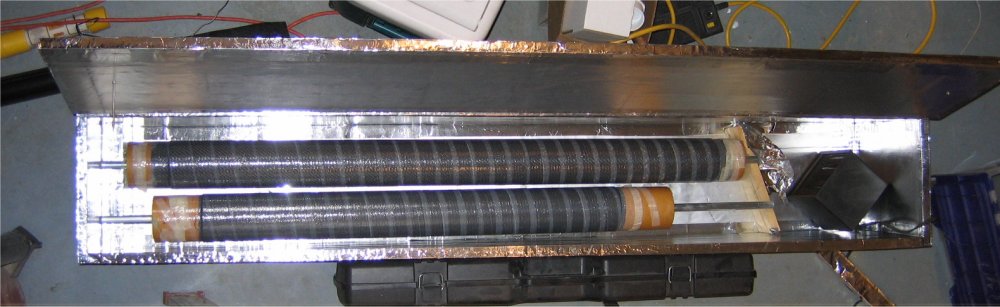

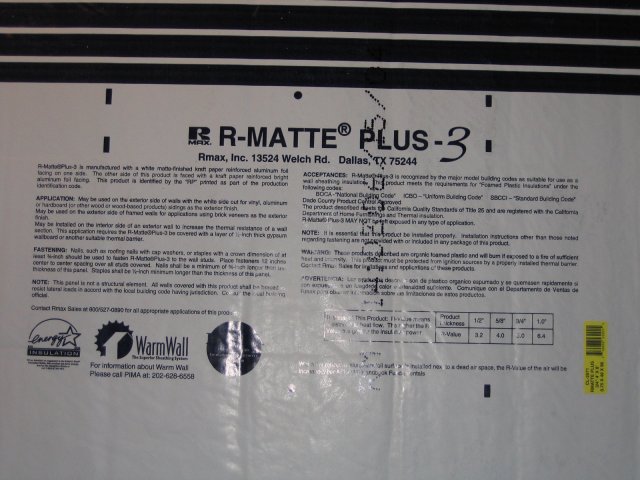

As built. 12" x 12" x 6' Built from a single sheet of 3/4" R-Matte Plus 3 insulation board. The variety you want has the factory foil facing on one side.

Tubes in the oven. Picture from my Reinforcing airframes page.

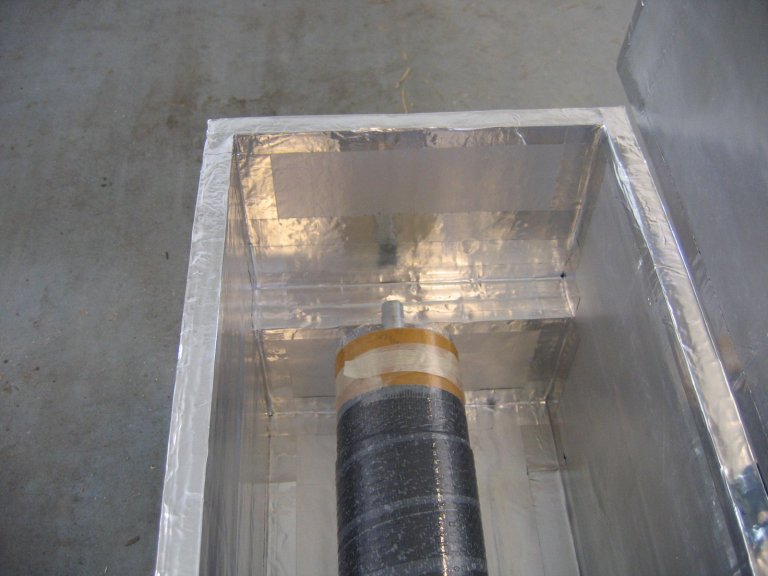

I built a small shelf on one end to support the ends. it's a doubled up section to give some extra support for tube rod fit. I also doubled up the foil tape in the area at shelf level so that the tube wouldn't puncture the foil lining during normal use.

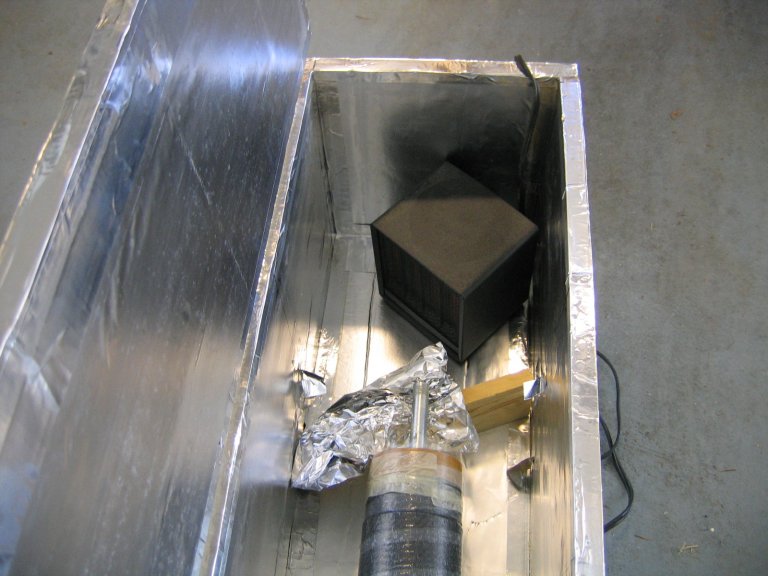

Heat source end support. Note the improvised wood block. I had a free standing bridge across the side, but the heat loosens the adhesive and when I inserted the tube the wieght popped the support out. I will either use a sparse inverted V support or put a rod of EMT or phenolic across.

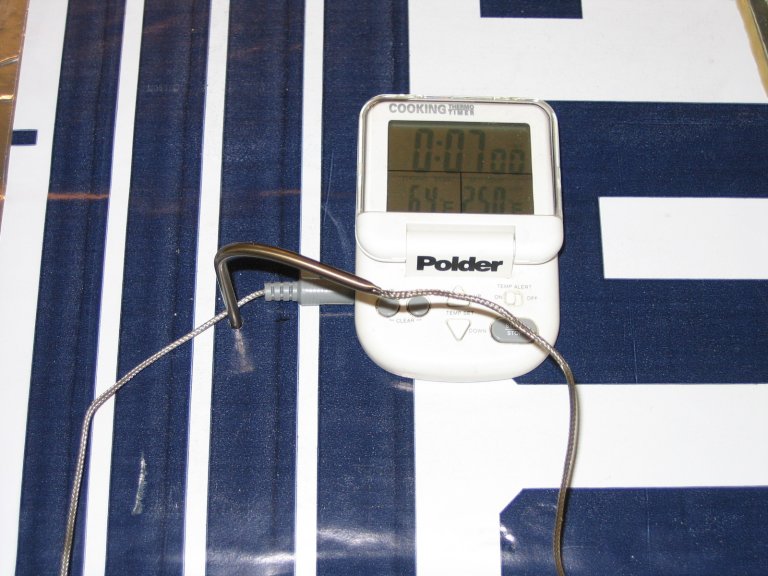

The kitchen Polder oven thermometer can handle the temperatures, and is useful for setting temperature alarms and also timing durations at various temperatures. You can see it's still set for a 250F heat shrink tape set run.

How do you attach hinges to crumbly foam board? with lots of surface area and PL-Premium polyurethane construction adhesive. Use no other.

Regular duct take will be a gooey mess. This Foil Sealant tape is great stuff. I wish I knew about it 20 years ago! It's heavy metal foil with an adhesive. No cheese involved. And relatively inexpensive at about $6-$7 per roll. From better home centers or your friendly HVAC supply shop (Tell them you're building a Epoxy Composite Post Cure Oven and they'll be suitably impressed - even if you don't have an account with them!)

This is my insulation board of choice. More stable than the pink foam, particularly for the higher temperatures involved. And the right version of this comes with a foil lining on one side. The foil lining is key and you don't want the hassle of foil lining yourself. You might have to call around to find this, but it is worth it. I used 3/4" and wouldn't mind finding it thicker (up to 2" I think is available, though harder to find.).

1500 Watt Space Heater

Router Speed Controller.