Experimental Propellant Vacuum

Processing

Propellant Vacuum

ProcessingExperimental Propellant

Vacuum Processing

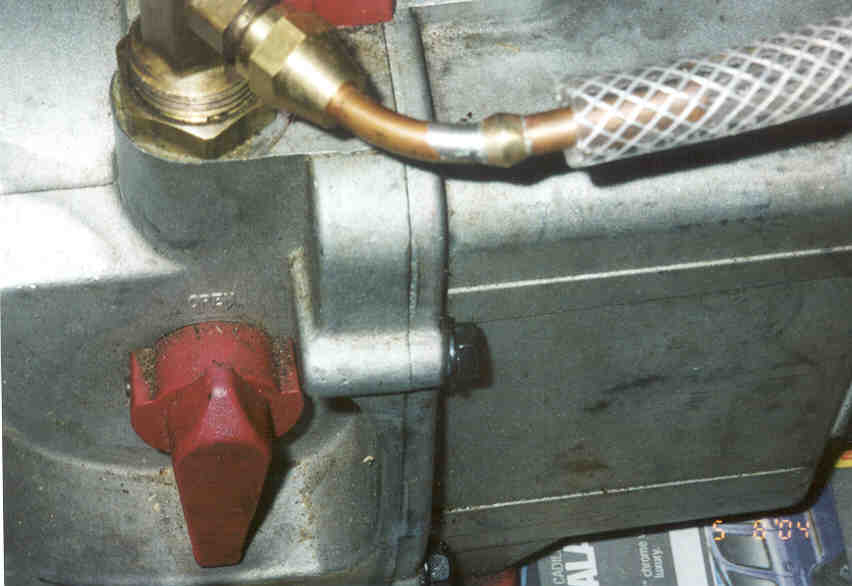

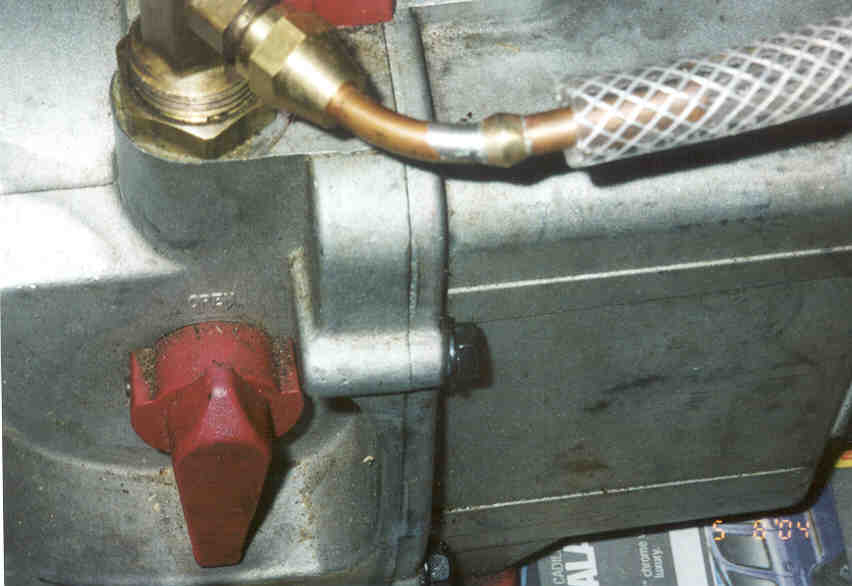

My vacuum pump is a RobinAir 6cfm unit as seen above. I picked it up

for $100 from a pawn shop. They seem to run $100-$140 +S&H on EBay.

It's got ample capacity and one could likley do with a smaller one.

The only issue with the RobinAir is that it will mist a bit. By this I

mean that the pump exhaust contains a small amount of ultra fine oil

mist. It's not very noticable for short runs but should preclude

running it inside one's house. Garage is OK. You can mitigate this to

some extent by laying a rag over the handle assembly (which contains

the vent). Don't plug the vent up, the pump isn't built for that,

merely provide a rag that will catch most of the mist.On a long run,

some oil film may run down the side of the motor adjacent to the

exhaust hole.

With that caveat about misting, I otherwise must say that the RobinAir,

particularly a used one, is an impressive value. This particular model

will pull my mixing bowl down to 29+" Hg within a couple of seconds.

You need to watch the initial surges until the propellant settles down.

With this capacity (the 6cfm model), it's easy to set the vent ball

valve to a partial setting to hold lower vacuums in the chamber to

allow the propellant to settle without banging it or needing to watch

it religiously.

The plate is 1/2" Polycarbonate from U.S. Plastic Supply. I have

another 3/4" plate from a friend.

The gasket is roofing rubber EDPM and is a piece of some I bought from

Wickman as part of his rocket kit. It's got a rough pattern but with

this pump sucks down fast and fine without any holding to start it. You

can otherwise get it from well stocked home centers.

I came up with a

quick-disconnect vacuum fitting for propellant degassing.. I had this

1/4" reinforced

tubing (you can do with thinner) and it didn't suck down onto the

tubing so I soldered in a compression ferrule and it sucks up nicely to

it yet is easy to disconnect.